PLCs, or programmable logic controllers, are essential to industrial automation because they can monitor and manage a wide range of activities. The Micro800 series is a well-liked option because to its adaptability and small size. We will look at how to use the specific programming software to modify the IP address of a Micro800 PLC in this blog article.

1. Software Overview:

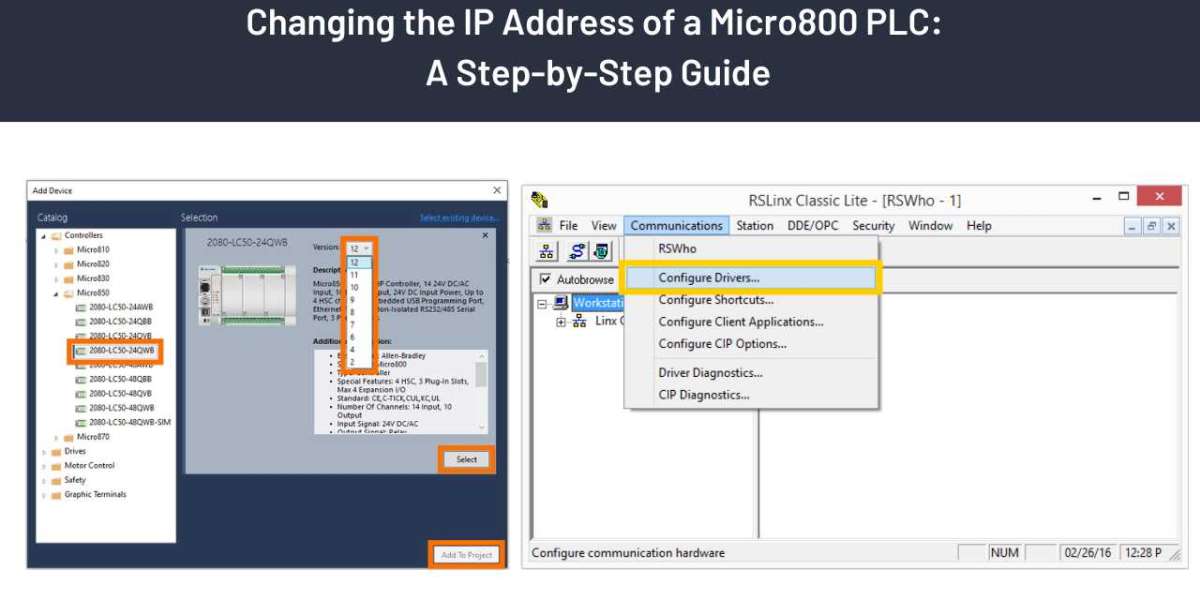

Rockwell Automation Micro800 PLC's IP address may only be modified with the use of the Connected Components Workbench (CCW) software. The programming environment CCW, which offers an intuitive interface for configuration and programming chores, was created especially for the Micro800 series controllers.

Rockwell Automation created the reliable and easy-to-use Connected Components Workbench (CCW) software, which is designed especially for Micro800 series programmable logic controllers (PLCs). This all-inclusive application offers technicians and engineers a user-friendly graphical interface for creating automation projects.

With CCW, ladder logic programming is supported for a number of Micro800 PLC types, allowing users to write and edit programmes. To effortlessly integrate PLCs into industrial contexts, users may specify connection protocols (such Ethernet/IP) and set up I/O configurations and network settings using the software's flexible setup tools.

2. Connecting to the PLC:

Use a USB cord to connect your computer to the Micro800 PLC before attempting to modify the IP address. Open the project linked to your PLC by launching CCW.

Make sure your Micro800 PLC is switched on correctly and that a USB cable is plugged into your PC. Typically, the PLC's USB port is found on its side or front.

Verify that your computer has the Micro800 series USB driver installed. The driver may be downloaded from the Rockwell Automation website or come pre-installed with the CCW software.

Launch the CCW programme on your PC. Download and install the software from the Rockwell Automation website if it isn't already installed.

With your Micro800 PLC, you may open an existing project or start a new one.

Check :- Allen Bradley Micro820 Programmable Controller

3. Navigate to Ethernet Configuration:

After connecting, open CCW and find the Ethernet setup section. This is the location where you may change the PLC's IP address settings.

- Launch Connected Components Workbench: Launch the CCW application on your PC and choose the project linked to your Micro800 PLC.

- Connect to the PLC: Make sure the USB connection connecting your Micro800 PLC to your PC is inserted correctly. Verify that the PLC is online by checking the connection status in the Controller Organiser or a comparable section.

- Open Controller Organizer: To manage your PLC controllers, find and open the "Controller Organiser" or a comparable area in CCW. Usually, you may find this on the toolbar or navigation pane.

- Select the Micro800 PLC: Find and pick your Micro800 PLC in the Controller Organiser. This need to show comprehensive PLC details, such as its name, firmware version, and communication status.

4. Locate the Ethernet Adapter:

Determine which particular Ethernet adapter is connected to your Micro800 PLC. To make sure that the modifications are applied to the appropriate network interface, this information is crucial.

Make sure a USB cable is used to connect your Micro800 PLC to your PC. Verify that the PLC is online by checking the connection status in the Controller Organiser or a comparable section.

To manage your PLC controllers, find and open the "Controller Organiser" or a comparable area in CCW. Usually, you may find this on the toolbar or navigation pane.

5. Modify IP Address Settings:

Find the IP address, subnet mask, and gateway entries in the Ethernet configuration section. In accordance with the specifications of your network, enter the updated IP address values. Make that the newly assigned IP address is not already in use and is unique.

Make sure the USB cable connecting your Micro800 PLC to your PC is in place, and make sure the PLC is online based on the connection status displayed in the Controller Organiser or a comparable area.

To manage your PLC controllers, find and open the "Controller Organiser" or a comparable module inside CCW. Usually, you may find this on the toolbar or navigation pane.

6. Apply Changes:

Apply the adjustments after inputting the new IP address settings. You will be prompted by CCW to download the PLC's setup. Verify the download in order to send the controller's updated settings.

7. Test the Connection:

Check that the IP address change was successful by connecting your PC and the Micro800 PLC. To make sure the PLC reacts to the new IP address, you can use the "Ping" command.

8. Save the Project:

Once you have confirmed that the IP address change is successful, save the project in CCW to preserve the updated configuration. This step is crucial for future reference and to avoid any discrepancies in the project file.

Changing the IP address of a Micro800 PLC is a straightforward process with the right tools and steps. Using the Connected Components Workbench software, you can modify the Ethernet configuration, apply changes, and ensure seamless integration into your industrial network. Always follow best practices and document any configuration changes to maintain a well-documented and organized control system.

When you need to scheduling regular maintenance for the the Allen Bradley Micro820 PLC Systems, Asteam Techno Solutions Pvt Ltd is here to help you. With an inventory of obsolete and surplus spare parts and a team of qualified engineers, there’s no breakdown or fault we cannot solve. Wherever you are in the world, Asteam Techno Solutions Pvt Ltd is the best Industrial Automation parts supplier and solutions provider in India as well as globally. Get support for all types of equipment from AC, DC and servo drives through to PLCs, HMIs and other automation parts.