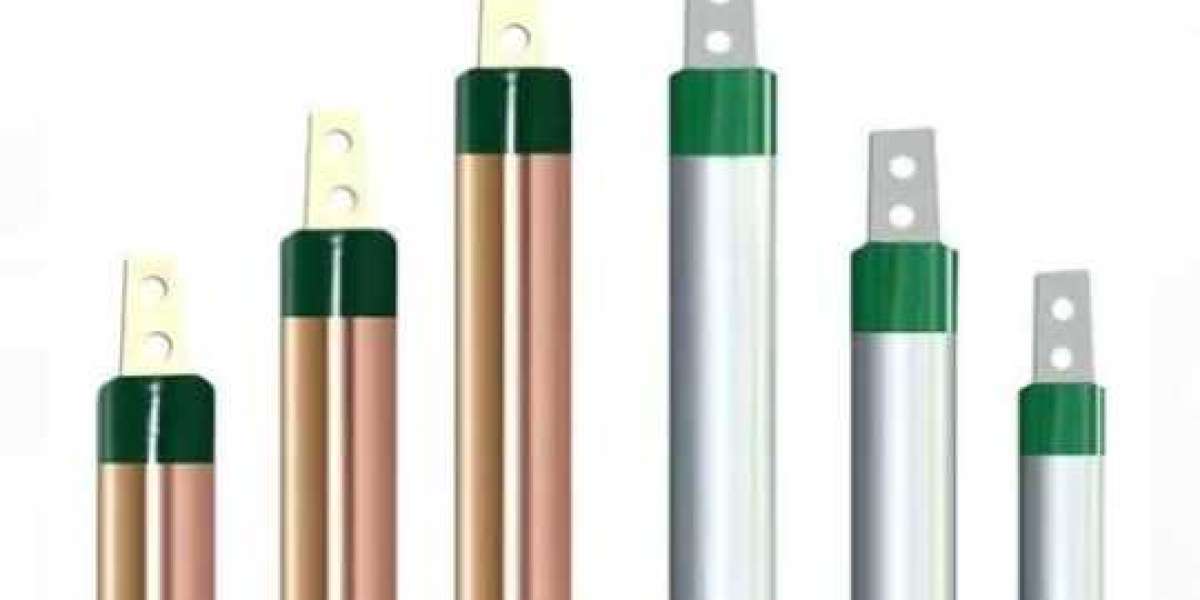

Printed Circuit Boards (PCBs) form the backbone of electronics, serving since the crucial platform for connecting and supporting various electronic components. As technology advances, the demand for smaller, lighter, and more powerful devices has driven the evolution of PCB manufacturing techniques. High-Density Interconnect (HDI) PCB technology has emerged as a revolutionary solution, allowing for the development of compact and highly efficient electronic devices.

What is HDI PCB?

HDI PCB, or High-Density Interconnect PCB, refers to a specialized type of printed circuit board designed to support a greater density of components and interconnections inside a smaller footprint. This technology addresses the challenges posed by the ever-increasing complexity of electronic devices, offering a better and compact solution in comparison to traditional PCBs.

Key Top features of HDI PCB:

Increased Component Density:

HDI PCBs leverage advanced design and manufacturing techniques to reach higher component density. That is accomplished by placing components in closer proximity and utilizing multiple layers for routing.

Reduced Size and Weight:

With the capability to support more components in just a smaller space, HDI PCBs donate to the miniaturization of electronic devices. This reduction in size and weight is very beneficial in applications such as for example smartphones, wearables, and medical devices.

Enhanced Signal Integrity:

HDI PCBs incorporate finer lines and spaces, reducing signal transmission distances. This, subsequently, enhances signal integrity and minimizes the chance of signal interference, making them suitable for high-frequency applications.

Increased Connection Reliability:

The usage of advanced manufacturing techniques, such as laser drilling and microvias, enables more precise and reliable connections between different layers of the PCB. This results in improved electrical performance and signal transmission.

Multilayer Structure:

HDI PCBs typically include multiple layers, including microvia layers, buried vias, and blind vias. This complex multilayer structure makes for intricate routing of signals and power, enabling efficient interconnections between components.

Applications of HDI PCB:

Consumer Electronics:

HDI PCBs find widespread use in consumer electronics, including smartphones, tablets, and smartwatches. The technology allows manufacturers to pack more features into smaller devices without compromising performance.

Medical Devices:

In the medical industry, where size and reliability are crucial factors, HDI PCBs play a vital role. Devices such as implantable medical devices, diagnostic equipment, and monitoring devices benefit from the miniaturization capabilities of HDI technology.

Aerospace and Defense:

The aerospace and defense sectors require high-performance and reliable electronic systems. HDI PCBs meet these demands by providing a tight and lightweight solution for avionics, radar systems, and communication flexible pcb.

Automotive Electronics:

As automotive electronics be more sophisticated, HDI PCBs are employed in applications such as for example advanced driver-assistance systems (ADAS), infotainment systems, and engine control units.

Conclusion:

High-Density Interconnect PCB technology represents a substantial revolution in the field of electronics manufacturing. Its ability to aid increased component density, reduce size and weight, enhance signal integrity, and improve connection reliability causes it to be an essential enabler for the development of advanced gadgets across various industries. As technology continues to advance, the role of HDI PCBs probably will become even more prominent in shaping the continuing future of electronic design and manufacturing.