The global thermal interface materials market size reached approximately USD 3.95 billion in 2023. The market is projected to grow at a CAGR of 10.10% between 2024 and 2032, reaching a value of nearly USD 7 billion by 2032. In today's electronic landscape, where devices are becoming increasingly compact and powerful, efficient thermal management is paramount to ensuring optimal performance and reliability. Thermal interface materials (TIMs) play a critical role in this process, acting as conduits for heat transfer between electronic components and heat sinks or other cooling devices. However, with a myriad of TIM options available in the market, selecting the right material for specific electronic applications can be a daunting task. In this comprehensive guide, we will delve into the intricacies of choosing the perfect thermal interface material for your electronics, covering everything from understanding TIMs to factors influencing selection, types of applications, case studies, best practices, and more.

I. Understanding Thermal Interface Materials (TIMs): Thermal interface materials (TIMs) are substances used to improve the heat transfer between two surfaces in contact, typically between electronic components and heat sinks or other cooling devices. TIMs serve as bridges between uneven surfaces, filling microscopic gaps and imperfections to facilitate efficient heat dissipation. Understanding the types, properties, and characteristics of TIMs is essential for selecting the most suitable material for a given electronic application.

Types of Thermal Interface Materials: Several types of TIMs are available in the market, each with its unique properties and applications:

- Thermal Greases: Also known as thermal compounds or thermal paste, thermal greases are viscous substances typically composed of silicone or non-silicone-based materials filled with thermally conductive particles such as metal oxides or ceramics. Thermal greases are commonly used in applications where there is a need for good thermal conductivity and conformability, such as between a CPU or GPU and a heat sink.

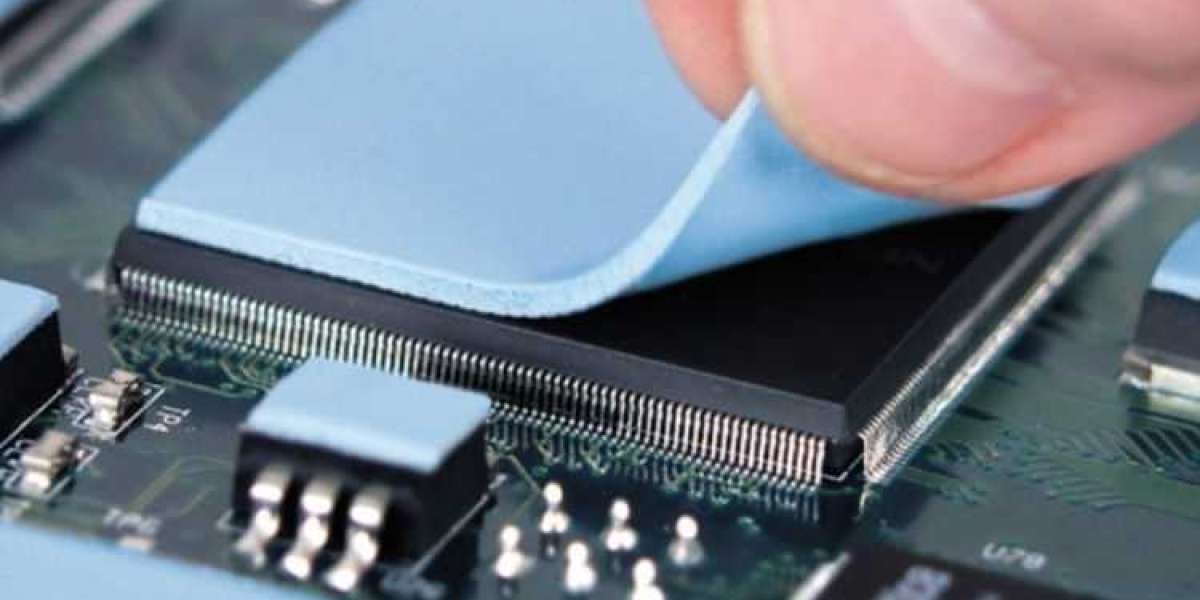

- Thermal Pads: Thermal pads, also known as thermal interface pads or thermal gap fillers, are soft, compressible pads made from materials like silicone or graphite infused with thermally conductive particles. These pads are pre-cut to fit specific electronic components and are often used in applications where ease of installation and reworkability are essential.

- Thermal Tapes: Thermal tapes are adhesive-backed tapes coated with a layer of thermally conductive material, such as acrylic or silicone-based compounds filled with thermally conductive particles. These tapes provide a convenient and mess-free solution for bonding electronic components to heat sinks or other surfaces, making them ideal for applications with space constraints or irregular shapes.

- Phase Change Materials (PCMs): Phase change materials are substances that change phase from solid to liquid or vice versa in response to temperature changes, absorbing or releasing heat in the process. PCMs offer excellent thermal conductivity and are commonly used in applications requiring high thermal energy storage capacity and thermal cycling performance, such as between power electronic components and heat sinks.

- Gap Fillers: Gap fillers, also known as thermal gap pads or thermal gap fillers, are soft, compressible materials designed to fill gaps and voids between electronic components and heat sinks or other surfaces. These materials are typically made from silicone or silicone-based compounds filled with thermally conductive particles and offer excellent thermal conductivity and conformability, making them ideal for applications with uneven or irregular surfaces.

Properties and Characteristics of TIMs: When selecting a TIM for a specific application, it's essential to consider the following properties and characteristics:

- Thermal Conductivity: The ability of a material to conduct heat, typically measured in watts per meter-kelvin (W/m·K). Higher thermal conductivity values indicate better heat transfer capabilities, resulting in lower thermal resistance and improved thermal performance.

- Thermal Impedance: The measure of a material's resistance to heat flow, typically measured in degrees Celsius per watt (°C/W). Lower thermal impedance values indicate lower thermal resistance and better thermal performance.

- Electrical Insulation: The ability of a material to insulate against electrical current, particularly important in applications where electrical isolation is required to prevent short circuits or electrical damage to components.

- Compressibility and Conformability: The ability of a material to deform and conform to irregular surfaces, ensuring intimate contact between the TIM and the electronic components or heat sink for maximum heat transfer efficiency.

- Long-term Reliability: The durability and stability of a TIM over time, including factors such as thermal stability, resistance to degradation from environmental factors like temperature, humidity, and mechanical stress, and long-term performance under operating conditions.

II. Factors to Consider When Choosing TIMs: Several factors influence the selection of thermal interface materials for electronics:

- Application Requirements: The specific requirements and operating conditions of the electronic device, including power density, operating temperature range, and environmental conditions such as humidity, vibration, and exposure to chemicals or contaminants.

- Compatibility: The compatibility of the TIM with the materials used in the electronic components and heat sink or other surfaces, including substrate materials (e.g., metals, ceramics, plastics), surface roughness and flatness, and electrical conductivity requirements.

- Installation Considerations: Practical considerations related to the installation and assembly of the TIM, including ease of application, thickness control and uniformity, cure time and curing methods (if applicable), and mechanical attachment methods such as adhesive backing, pre-applied films, or mechanical fasteners.

III. Types of Electronic Applications and TIM Selection: Different electronic applications require specific types of TIMs tailored to their unique requirements:

- CPUs and GPUs: High-performance processors such as central processing units (CPUs) and graphics processing units (GPUs) generate significant amounts of heat during operation and require efficient thermal management to prevent overheating and ensure optimal performance. Thermal greases and phase change materials are commonly used in these applications for their high thermal conductivity and conformability.

- LEDs and Lighting Systems: Light-emitting diodes (LEDs) and lighting systems require effective thermal management to dissipate heat generated by the LEDs and prolong their lifespan. Thermally conductive adhesives and gap fillers are commonly used in these applications for their ability to bond LED modules to heat sinks and provide reliable thermal coupling.

- Power Electronics: Power electronic components such as insulated gate bipolar transistors (IGBTs), diodes, and power transistors require efficient thermal management to dissipate heat generated during operation and prevent thermal runaway. Thermal pads and gap fillers are commonly used in these applications for their high thermal conductivity and compressibility.

- Automotive Electronics: Automotive electronic systems such as engine control units (ECUs), infotainment systems, and electric vehicle (EV) battery packs require robust thermal management solutions to withstand harsh operating conditions and temperature fluctuations. Silicone-based thermal pads and gap fillers are commonly used in automotive applications for their thermal stability, reliability, and resistance to environmental factors.

IV. Case Studies and Real-world Examples: Examining real-world scenarios and case studies can provide valuable insights into the selection and application of TIMs in electronic devices:

- Case Study 1: Selecting TIMs for a High-Performance Gaming PC Build In this case study, we explore the process of selecting thermal interface materials for a high-performance gaming PC build, considering factors such as CPU and GPU compatibility, thermal performance requirements, and ease of installation.

- Case Study 2: Thermal Management Solutions for LED Street Lighting Systems In this case study, we examine the use of thermal interface materials in LED street lighting systems to improve thermal performance, increase reliability, and prolong LED lifespan, considering factors such as heat dissipation requirements, environmental conditions, and long-term reliability.

- Case Study 3: TIM Selection for Automotive Infotainment Systems In this case study, we investigate the selection of thermal interface materials for automotive infotainment systems, considering factors such as temperature fluctuations, vibration resistance, and compatibility with automotive materials and substrates.

V. Best Practices and Tips for TIM Selection: Implementing best practices and tips can help optimize thermal performance and reliability in electronic devices:

- Conduct Thorough Thermal Analysis and Testing: Perform comprehensive thermal analysis and testing to evaluate the thermal performance of different TIMs under simulated operating conditions and determine the most suitable material for the application.

- Consider Long-term Reliability and Durability: Prioritize TIMs with excellent long-term reliability and durability, considering factors such as thermal stability, resistance to degradation from environmental factors, and long-term performance under operating conditions.

- Consult with TIM Manufacturers and Experts: Seek guidance and expertise from TIM manufacturers and experts to ensure informed decision-making and optimize TIM selection for specific electronic applications.

- Optimize TIM Application Techniques: Optimize TIM application techniques for best results, ensuring proper thickness control and uniformity, adequate coverage of the contact surfaces, and proper curing or bonding for reliable thermal coupling.