you’ll have all the knowledge you need to confidently use SMT assembly to tackle your most ambitious projects. From assessing components to soldering techniques, this guide will provide the essential knowledge and skills you need to become an SMT assembly expert. With the right information, you’ll be able to create products that are both innovative and reliable. So get ready to learn the fundamentals of SMT assembly and become an electronics engineering master!

Assessing SMT Components

The first step to SMT assembly is assessing the components you plan to use. This allows you to determine whether the components are suitable for SMT assembly. It will also help you identify the components you need for your project. What is the best way to assess components? One of the most important considerations when assessing components for SMT assembly is their size. You’ll need to ensure that the components are small enough to fit inside the SMT assembly process. In general, passives, small connectors, and ICs are ideal for SMT assembly. However, there are some components that are too large to use with SMT. For instance, a barrel jack is too large to be used with SMT. This is why it’s so important to assess components before you start an SMT assembly project. If you’re unsure whether a component can be used for SMT, it’s best to just avoid using it.

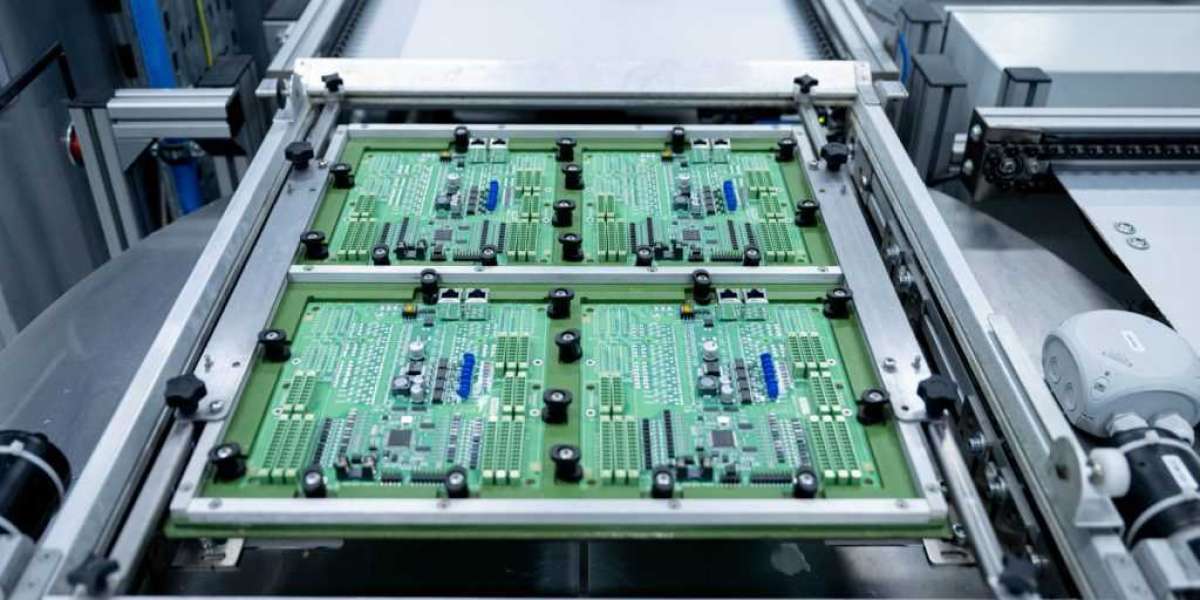

SMT Placement Equipment

When it comes to SMT placement equipment, you have a few options to choose from. The first type of placement equipment is an SMT pick-and-place machine. This machine is similar to the pick-and-place machines used for through-hole assembly. However, the machine is adjusted to handle smaller components. The next type of placement equipment is an SMT re-flow soldering oven. This oven can be used for both through-hole and SMT assembly. However, it’s not a pick-and-place machine. The last type of placement equipment is an SMT placement machine. This machine is completely dedicated to SMT assembly. It has the ability to place SMT components onto PCBs with a robotic arm. While each placment method has its own advantages and disadvantages, the placement equipment for SMT assembly can vary greatly depending on several factors. The first factor is the production volume of your electronics manufacturing company. The larger your operation is, the more likely you’ll have access to a placement machine. The second factor is the type of product you’re manufacturing. While pick-and-place machines are the most common SMT placement equipment, a placement machine can be used in place of a pick-and-place machine.

Soldering Techniques for SMT Assembly

There are two soldering techniques to use when soldering SMT components. The first technique is reflow soldering. This is the standard soldering method used for through-hole assembly. However, it is slightly modified for use with SMT. The second technique is wave soldering. This method is more commonly used for traditional SMT assembly, where the components are placed in a tray and then soldered. To use reflow soldering, you’ll need a solder paste stencil, reflow oven, heated solder tray, and a solder squeegee. To use wave soldering, you’ll need a tray, pick-up tool, hot plate, and a bubble blaster. Regardless of which soldering method you use, there are a few key things to keep in mind. The first thing is to make sure each component is clean and dry. If any moisture is present, it may cause the solder to form a poor joint. Next, it’s important to select the right solder type. You want to use a lead-free solder that is ideal for SMT assembly. While it may take more time to use these soldering techniques, they are essential for creating a product with high-quality joints.

Best Practices for SMT Assembly

The best practices for SMT assembly depend on the type of project you’re working on. However, there are a few practices that apply to all types of projects. The first practice is to always use a printed circuit board (PCB). A PCB is the standard surface for SMT assembly. This is why you want to make sure you’re using a PCB for your project. Next, make sure your PCB is designed for SMT assembly. A PCB designed for SMT assembly will have a grid on the back, which is used as a guide for placement. The last practice to use while performing SMT assembly is to always use a stencil. A stencil is used to place the components on the PCB. If you don’t use a stencil, there is a high chance you’ll get the components in the wrong place. Along with these best practices, there are a few tips to keep in mind when performing SMT assembly. The first tip is to use the right tools for the job. This includes using the right soldering iron, tweezers, and solder. Another tip is to keep your work area clean. This will help you avoid making mistakes when placing the components.

Troubleshooting and Maintenance Tips

The best way to troubleshoot and maintain SMT assembly is to follow a consistent process. This will help you recognize any issues with your assembly and resolve them before they become bigger problems. First, use a visual inspection to look for any issues with the assembly. If you see something wrong, correct it immediately. The next step is to inspect the PCB carefully to make sure everything is placed correctly. You should also use an inspection microscope to look at the solder joints to make sure they are correct. After this, check the components and make sure there are no loose connections. Finally, it’s a good idea to test the product after assembly to make sure it’s working as it should. The last step is to make sure you properly maintain your SMT assembly equipment. This includes cleaning the equipment regularly and storing it in a safe location.

Calculating Cost-Effectiveness of SMT Assembly

Before you decide to use SMT assembly on a project, it’s important to calculate its cost-effectiveness. This will help you determine whether SMT assembly is the most cost-effective option for your project. The first factor to consider is the design of the product. If your design can be easily adapted for SMT assembly, it’s a good idea to use it for your project. Next, find out how many components are necessary for your design. The more components you need, the more likely it is that you’ll want to use SMT assembly. Finally, it’s important to factor in your design and component costs. This will help you determine how much it will cost to use SMT assembly. Once you have this information, you’ll be able to determine whether SMT assembly is the best option for your project.

Resources for Professional Electronics Engineers

If you want to become an expert in SMT assembly, there are many resources you can turn to. First, it’s a good idea to read about SMT assembly online. There are many blogs and tutorial sites that can help you learn about SMT assembly. You can also attend in-person training to learn more about SMT assembly. Finally, you can take a class at a nearby university. Many universities offer engineering classes that cover the basics of SMT assembly. No matter where you get your education, the more you know about SMT assembly, the better engineer you’ll be. Once you have all the knowledge and skills you need, you’ll be ready to create complex products with minimal time and effort. With the right information, you’ll be able to confidently use SMT assembly to tackle your most ambitious projects.