Crude Oil and Natural Gas Production:

In the upstream sector of the oil and gas industry, centrifugal pumps are extensively used in crude oil and natural gas production. These pumps play a vital role in lifting crude oil from wells to the surface. Submersible centrifugal pumps are often deployed in wellbore applications, where they efficiently lift fluids containing a mix of oil, gas, and water. The ability of centrifugal pumps to handle a range of fluid compositions makes them indispensable in optimizing production rates and maintaining operational efficiency.

Water Injection Systems for Enhanced Oil Recovery (EOR):

Enhanced Oil Recovery (EOR) techniques, including water injection, are employed to maximize oil extraction from reservoirs. Centrifugal pumps are integral components of water injection systems, where they pressurize and inject water into reservoirs to displace oil towards production wells. The reliability and adaptability of centrifugal pumps make them ideal for handling the demanding conditions associated with EOR processes, contributing to increased oil recovery rates.

Pipeline Transportation:

Transporting crude oil and natural gas over vast distances requires robust and efficient pumping systems. Centrifugal pumps are widely utilized in pipeline transportation for their ability to provide continuous and steady fluid flow. These pumps maintain the required pressure levels to ensure the smooth movement of hydrocarbons through pipelines, from production fields to processing facilities and ultimately to distribution points. The reliability and scalability of centrifugal pumps make them a cornerstone in the infrastructure of pipeline networks.

Refinery Operations:

Within refineries, where crude oil is processed into various petroleum products, centrifugal pumps serve diverse functions. These pumps handle tasks such as transferring crude oil between processing units, circulating cooling water, and boosting the pressure of various fluid streams. Their versatility, coupled with the ability to handle varying viscosities and temperatures, makes centrifugal pumps essential for maintaining the intricate fluid dynamics required in refining operations.

Petrochemical Processing:

The petrochemical industry relies on centrifugal pumps for the transfer and circulation of various chemical compounds derived from crude oil. These pumps facilitate the movement of feedstocks and intermediate products between different processing units within petrochemical plants. The ability of centrifugal pumps to handle corrosive and abrasive substances, coupled with their efficiency, makes them vital in ensuring the smooth operation of complex petrochemical processes.

Offshore Platforms:

In offshore oil and gas production, where platforms are situated in remote and challenging environments, centrifugal pumps play a crucial role in managing fluid dynamics. They are employed for lifting crude oil from subsea wells to surface platforms, circulating cooling water, and providing essential services for platform utilities. The compact design and adaptability of centrifugal pumps make them well-suited for the space constraints and harsh conditions associated with offshore operations.

Firewater Pumping Systems:

Safety is a paramount concern in the oil and gas industry, and centrifugal pumps are integral to firewater pumping systems on both onshore and offshore facilities. These pumps are designed to provide high-pressure water for firefighting in the event of an emergency. The reliability and rapid response capability of centrifugal pumps are critical for ensuring the safety of personnel and assets in the event of a fire incident.

Gas Processing and Compression:

Centrifugal pumps play a role in gas processing facilities by assisting in the compression and transportation of natural gas. They are employed in gas compression units to boost the pressure of natural gas for pipeline transportation. The efficiency and adaptability of centrifugal pumps make them suitable for handling the varying pressures and flow rates associated with gas processing operations.

Drilling Fluid Circulation:

During drilling operations, centrifugal pumps are utilized in the circulation of drilling fluids. These fluids serve multiple purposes, including cooling and lubricating the drill bit, carrying drill cuttings to the surface, and maintaining wellbore stability. Centrifugal pumps contribute to the efficient circulation of drilling fluids, ensuring the success and safety of drilling operations in exploration and production activities.

Wastewater Treatment:

As a byproduct of oil and gas production and refining, wastewater must be treated before disposal or reuse. Centrifugal pumps are employed in wastewater treatment plants to handle the transfer and circulation of wastewater for various treatment processes. Their robust construction and ability to handle liquids with solid particles make centrifugal pumps effective in supporting environmental sustainability efforts within the industry.

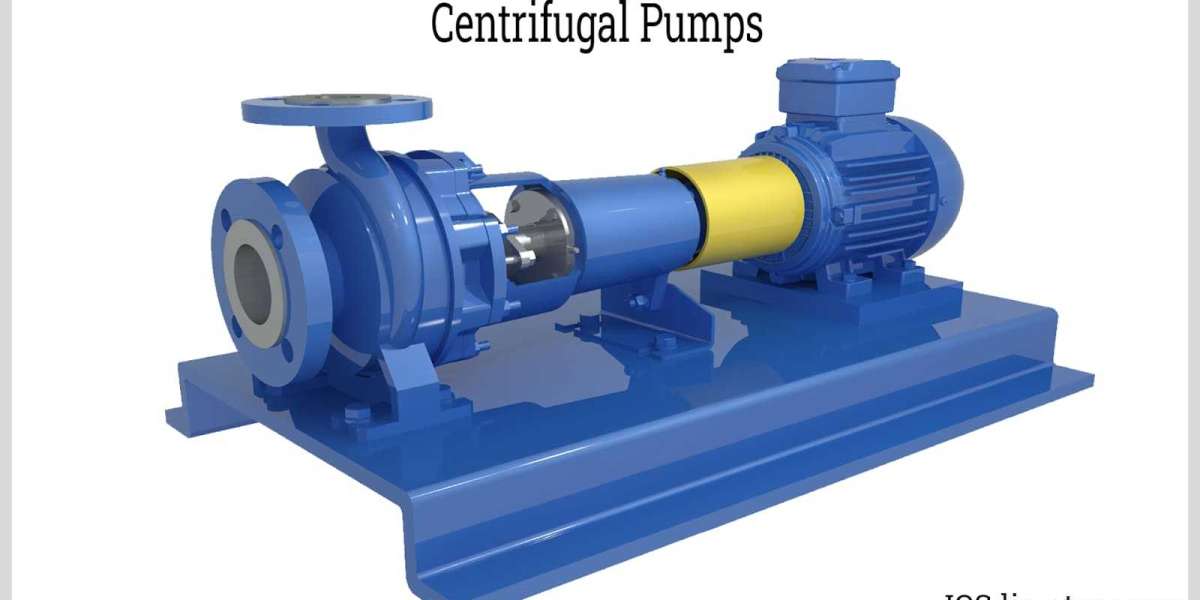

Final Thoughts:

The applications of centrifugal pumps in the oil and gas industry are diverse and integral to the entire lifecycle of hydrocarbon production and processing. From the extraction of crude oil to its transportation through pipelines, refining into valuable products, and even ensuring safety through firefighting systems, centrifugal pumps play a pivotal role. Their efficiency, adaptability, and reliability make them indispensable components in the complex and dynamic landscape of the oil and gas sector, contributing to the industry's ability to meet global energy demands.