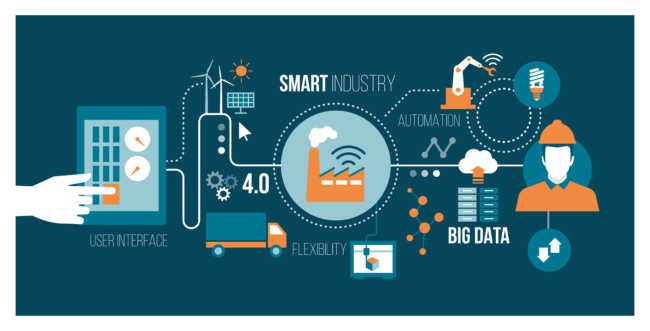

By connecting machines, devices, and systems through the internet, IIoT enables real-time data collection, analysis, and decision-making, ushering in a new era of smart manufacturing. Here’s a comprehensive look at the applications and benefits of iiot in manufacturing.

Enhancing Operational Efficiency

IIoT revolutionizes manufacturing by enhancing operational efficiency through automation and real-time monitoring. Connected sensors embedded in machinery and equipment gather data on performance metrics such as temperature, pressure, and speed. This data is transmitted to centralized systems where it is analyzed to identify patterns and anomalies. Predictive maintenance algorithms use this information to schedule maintenance proactively, reducing downtime and preventing costly equipment failures. By optimizing asset utilization and minimizing unplanned downtime, IIoT significantly boosts overall operational efficiency.

Improving Quality Control and Production Processes

Quality control is paramount in manufacturing, and IIoT plays a crucial role in ensuring product consistency and adherence to quality standards. IoT-enabled sensors monitor production processes in real-time, detecting variations and anomalies that could indicate potential defects. This immediate feedback allows manufacturers to implement corrective measures promptly, minimizing waste and improving product quality. Furthermore, IIoT facilitates the implementation of predictive quality analytics, where data-driven insights enable continuous improvement and optimization of production processes.

Facilitating Supply Chain Management

Effective supply chain management is essential for manufacturing competitiveness, and IIoT provides valuable tools for optimizing supply chain operations. IoT devices track inventory levels in real-time, enabling automatic replenishment and reducing stockouts. Moreover, sensors in transportation vehicles monitor shipment conditions such as temperature and humidity, ensuring product integrity throughout the supply chain. IIoT data analytics enhance supply chain visibility, allowing manufacturers to anticipate demand fluctuations, optimize logistics routes, and improve overall supply chain efficiency.

Enabling Smart Manufacturing Initiatives

IIoT serves as a cornerstone for smart manufacturing initiatives, where interconnected systems and advanced analytics drive autonomous decision-making and adaptive manufacturing processes. Through the integration of IoT devices, artificial intelligence (AI), and machine learning (ML), manufacturers can achieve greater agility and responsiveness. For example, AI-powered predictive maintenance systems can analyze historical and real-time data to forecast equipment failures accurately, enabling preemptive actions that prevent disruptions and optimize production schedules.

Enhancing Workplace Safety and Employee Efficiency

IIoT enhances workplace safety by monitoring environmental conditions and employee activities in real-time. Wearable IoT devices equipped with sensors can detect hazardous conditions and alert workers and supervisors promptly. Furthermore, IIoT data analytics identify safety trends and potential risks, enabling proactive measures to mitigate accidents and ensure compliance with safety regulations. By promoting a safer work environment, IIoT not only protects employees but also enhances overall productivity and efficiency.

Driving Innovation and Competitiveness

Innovation is a cornerstone of IIoT adoption in manufacturing, enabling companies to differentiate themselves in a competitive market. By leveraging real-time data and analytics, manufacturers can innovate new products, services, and business models. For instance, IIoT facilitates the development of connected products that provide value-added services such as remote diagnostics and predictive maintenance to customers. Furthermore, collaborative IIoT ecosystems enable partnerships and co-innovation opportunities that drive continuous improvement and sustainable growth.

Future Trends and Considerations

Looking ahead, the future of IIoT in manufacturing holds promising advancements in connectivity, cybersecurity, and interoperability. As the technology matures, manufacturers will increasingly integrate IIoT with other transformative technologies such as 5G networks and edge computing to enhance data processing speed and reliability. Moreover, ensuring robust cybersecurity measures will be critical to safeguarding sensitive IIoT data and maintaining trust in connected systems. As IIoT continues to evolve, manufacturers must prioritize interoperability standards to enable seamless integration across diverse systems and devices.

Conclusion

In conclusion, IIoT represents a paradigm shift in manufacturing, enabling unprecedented levels of connectivity, automation, and intelligence. By harnessing the power of real-time data and advanced analytics, IIoT drives operational excellence, improves product quality, optimizes supply chain efficiency, enhances workplace safety, and fosters innovation. As manufacturers continue to embrace digital transformation, the strategic adoption of IIoT solutions will be instrumental in unlocking new opportunities for growth, competitiveness, and sustainability in the global manufacturing landscape.

In summary, IIoT is not just a technological advancement but a catalyst for reshaping the future of manufacturing, empowering organizations to thrive in an increasingly interconnected and data-driven world.